Order quality turned parts online at mfgprocure. Attractive prices and fast service incl. Proof of testing with every order. Upload CAD file and receive quote within 48 hours

Fill out our simple registration form here to create and confirm your account.

Become a Partner to access Job Board where we match your company’s capabilities to production runs of all sizes from customers worldwide.

Get paid for the order via bank transfer based on the invoice from your company, in India.

Produce five real orders with good quality and timing to become a trusted partner. Being a trusted partner ensures access access to variety mfgprocure order

As a partner with MFGProcure, you unlock exclusive entry to an extensive clientele network in search of Casting, CNC machining, Sheet Metal, Injection Moulding, and 3D printing services.

Precision parts for aerospace, automotive, or industrial machinery, such as engine parts, structural components, or custom-made gears.

Custom enclosures for electronics, panels for appliances, or parts for automotive bodies, including computer server racks, air conditioner casings, or car body panels.

Precision cut parts for intricate model kits or architecturally significant decorative panels. This includes highly detailed parts for scale models and aesthetically pleasing screens for architectural applications.

Heavy-duty parts for construction equipment, custom signage for businesses, or unique metal artwork, like large-scale machinery parts, company logos, or metal sculptures.

Seals and gaskets for industrial machinery, custom molds for food production, or flexible parts for medical devices, like engine seals, chocolate molds, or silicone heart valves.

High-precision parts for aerospace applications, durable components for marine equipment, or custom shapes for composite material products, such as turbine blades, boat propellers, or carbon fiber frames.

Robust components for automotive engines, detailed parts for model toys, or high-volume hardware for furniture, such as engine blocks, miniature car models, or metal drawer handles.

Durable housings for consumer electronics, high-volume parts for toys, or specialized components for medical devices, such as smartphone cases, action figures, or casing for handheld medical devices.

Rapid prototypes for product development, complex geometries for medical devices, or low-volume production parts for specialized equipment, like product mock-ups, surgical guides, or drone components.

Our extensive network of skilled and specialized suppliers is the cornerstone of our wide-ranging capabilities and unwavering quality. The MFGprocure Network employs a rigorous selection and onboarding procedure to oversee and expand this network. With each new supplier we incorporate into the network, we adhere to a thorough 8-step process:

Fill out our simple registration form here to create and confirm your account. It is free.

We conduct an evaluation to see if the supplier meets Hubs qualification criteria We also provide detailed information on what it's like to work with Hubs.

A Hubs auditor assess quality management performance and environmental/social compliance.

Every Hubs supplier has to hold the right registrations and licenses. We do full background checks and sign formal agreements to ensure compliance

Once suppliers meet our standards, we give them access to the quote- building platform.

To ensure the process runs smoothly from ordering to delivery, we train every MP on the technical standards.

Supply chain managers monitor the first 10 orders of every new supplier. We perform on-site quality control for pre and post- production.

To ensure that our network meets and exceeds industry standards, we audit our MPs on a regular basis and drive continual improvement.

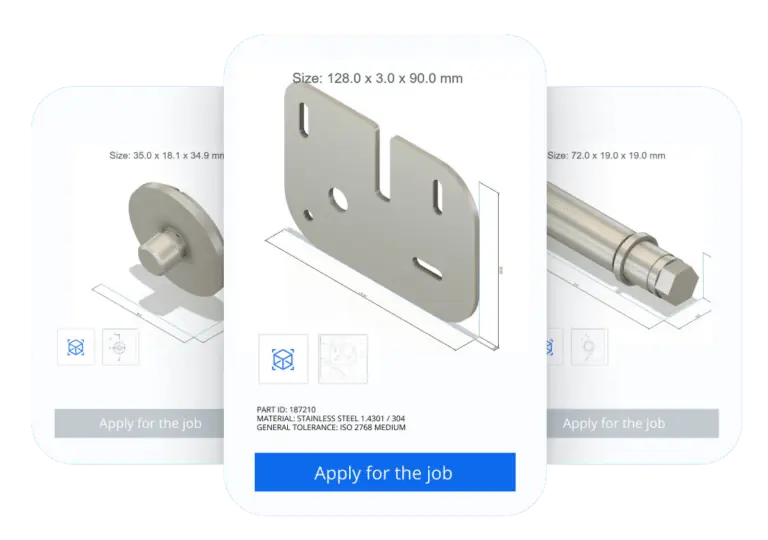

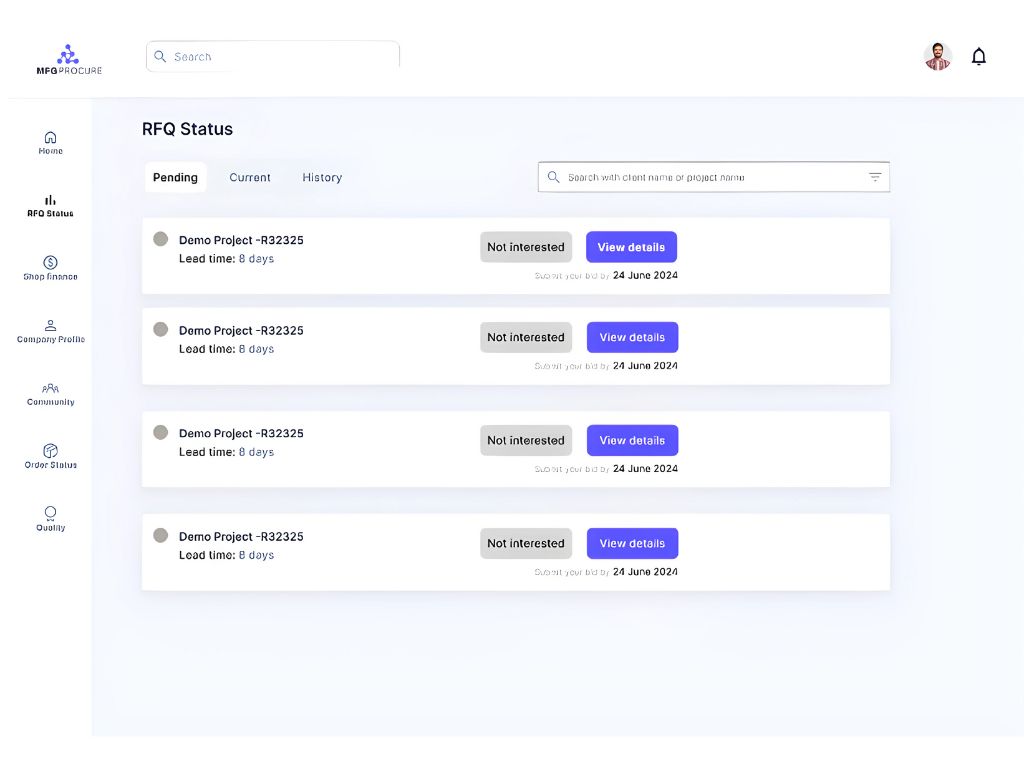

The MFGprocure Supplier Portal serves as your central hub for managing all orders. With just a glance, you can view your active inquiries and track the progress of ongoing orders. This platform allows you to effectively manage your available production capacities and adjust the number of requests as needed.

Our goal is to maintain a line item non-conformance rate of less than 1% and mitigate any part issues. In the event of issues, a corrective action plan is implemented. The responsible Manufacturing Professional identifies the root cause of the problem and enhances the process to prevent similar issues from occurring again. The MFGprocure Network Standards play a crucial role in ensuring that your parts are manufactured to specification.

Thanks to our highly vetted supplier network and ISO 9001-certified Quality Management System, it’s always possible to have your parts manufactured with industry-specific certifications. Our manufacturing partner network can certify to the following standards: ISO 9001, AS 9100, ISO 13485, ISO 14001 and ISO TS16949.

Our platform offers Local sourcing generally offers quicker turnaround times but comes with a higher cost. All 3D printing orders and some CNC orders are sourced locally, undergo quality checks by the manufacturer, and are directly shipped to you. International sourcing is typically more cost-effective. Certain complex CNC machining, injection moulding, and sheet metal orders can only be sourced globally. Depending on where they are manufactured and the complexity of the parts, globally sourced orders are initially sent to our cross-docking facilities in India for quality control inspections before being shipped to their final destinations.